Category: Clips

Robotic Boats?!

Here in the Makerspaces, another project that’s in process is the creation of a robotic boat, or more specifically, the creation of swarming autonomous boats (unmanned surface vehicles (USVs) if we’re being real shoes-and-tie fancy like). As both a platform for learning as well as for research; autonomous unmanned surface vehicles are a very relevant technical environment within which our students are working. Swarming USVs will have deep applications in the future ranging from shipping and transportation to deep water exploration and more.

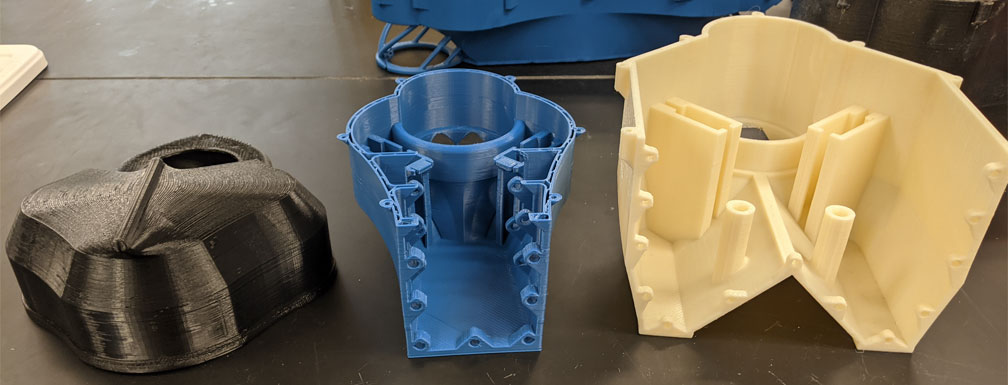

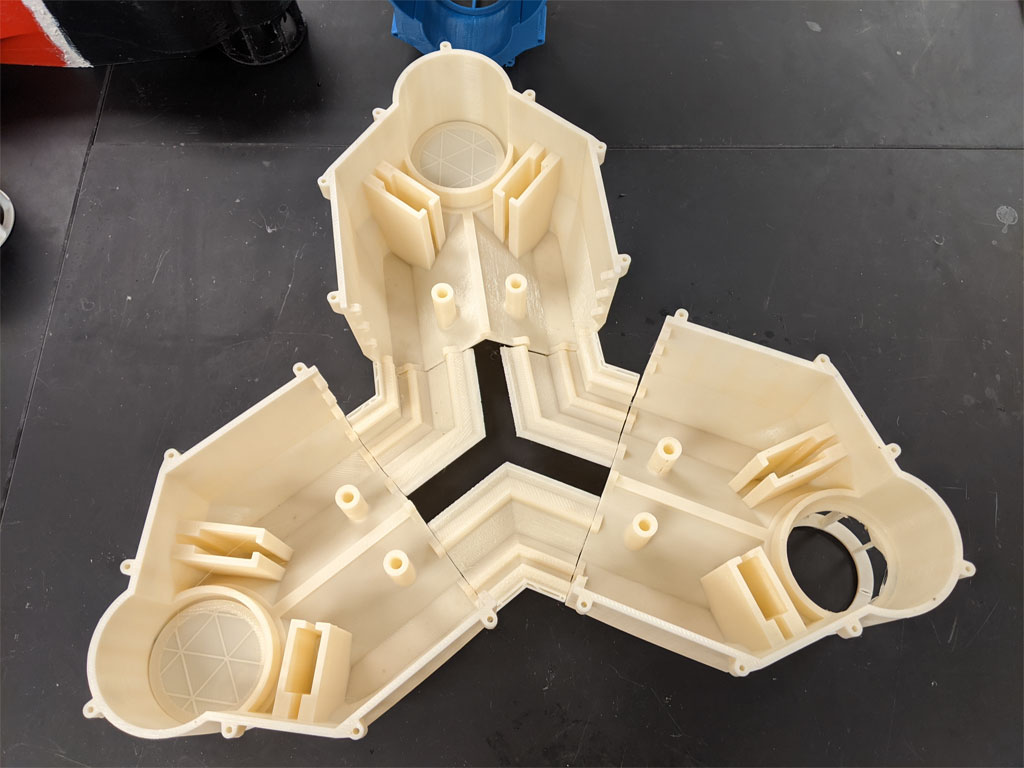

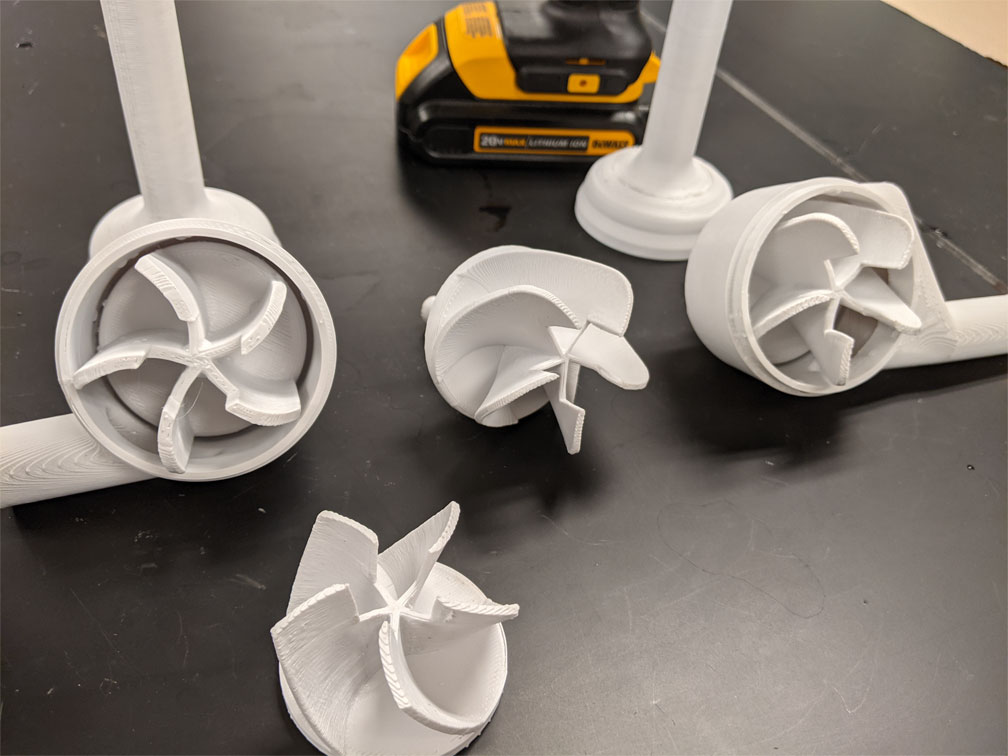

Starting small, our students are focusing on wholly 3D printed USV swarm member prototypes as shown below as we were preparing for a test launch from our Lake Matoaka docks back in January.

Over the past many months the students involved, in particular the Robotics Club, has explored hull design options and coding architectures on our way towards building an effective swarming USV member.

As can be seen these are clearly non-traditional boat hull designs. One of the big reasons that are so strange is that these USVs are based around a unique form of engine, Voith-Schneider propulsion (VSP) systems. VSP systems are quite unique in that they can almost instantaneously point a thrust vector in any cardinal direction. They look and operate similar to a helicopter blade that has been turned vertically and dunked into the water.

If this project sounds of interest to you, let the Makerspaces or the student Robotics Club know and come join the fun. We’ve got all the basic building blocks working and are heading to the Lake for testing.

What’s better than robotics at Lake Matoaka on a nice sunny day?!

Open Source Syringe Bot

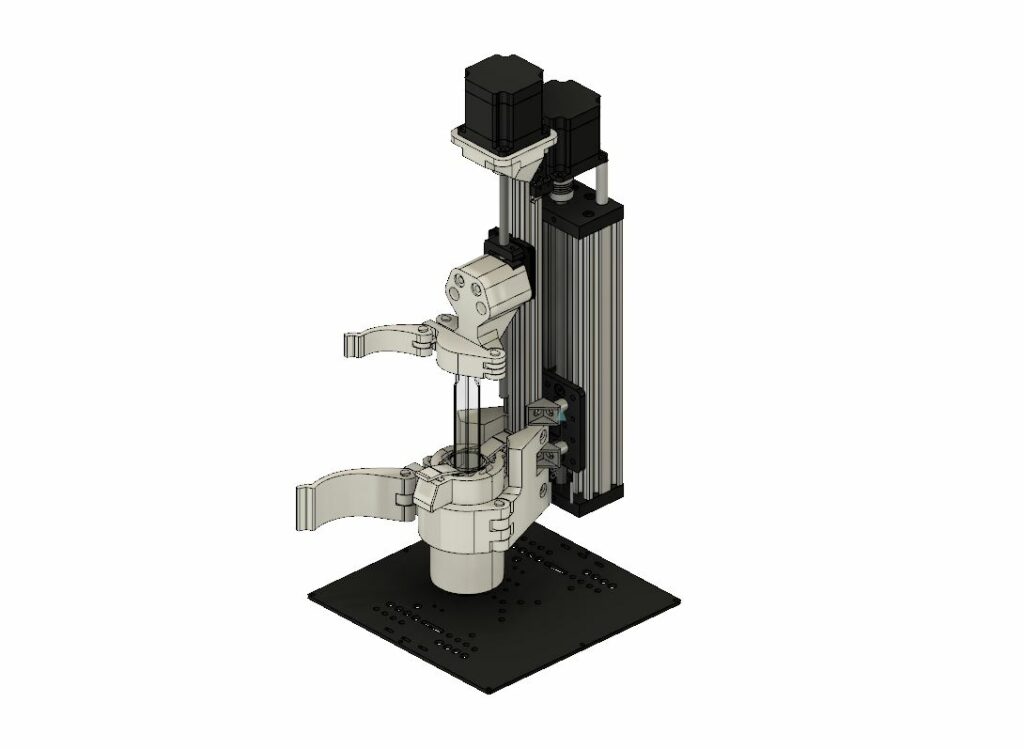

The Makerspaces at William & Mary have many projects underway, one of the more interesting is the creation of an open source syringe bot design that is ultra-low cost and high resolution. The concept is that there are so many instances when we need a simple robot to move around a syringe and squirt some goop for us; either to 3D print from viscous fluids and epoxies or to perform automatic titration and chemistry a robot can be useful. If we can make one that is ultra-low cost, as in a couple hundred bucks at most, and yet can maintain micrometer level positioning accuracies and micro (or even nano) liter level dispensation volumes, that robot could be truly useful!

Introducing syringeBot v0.1.

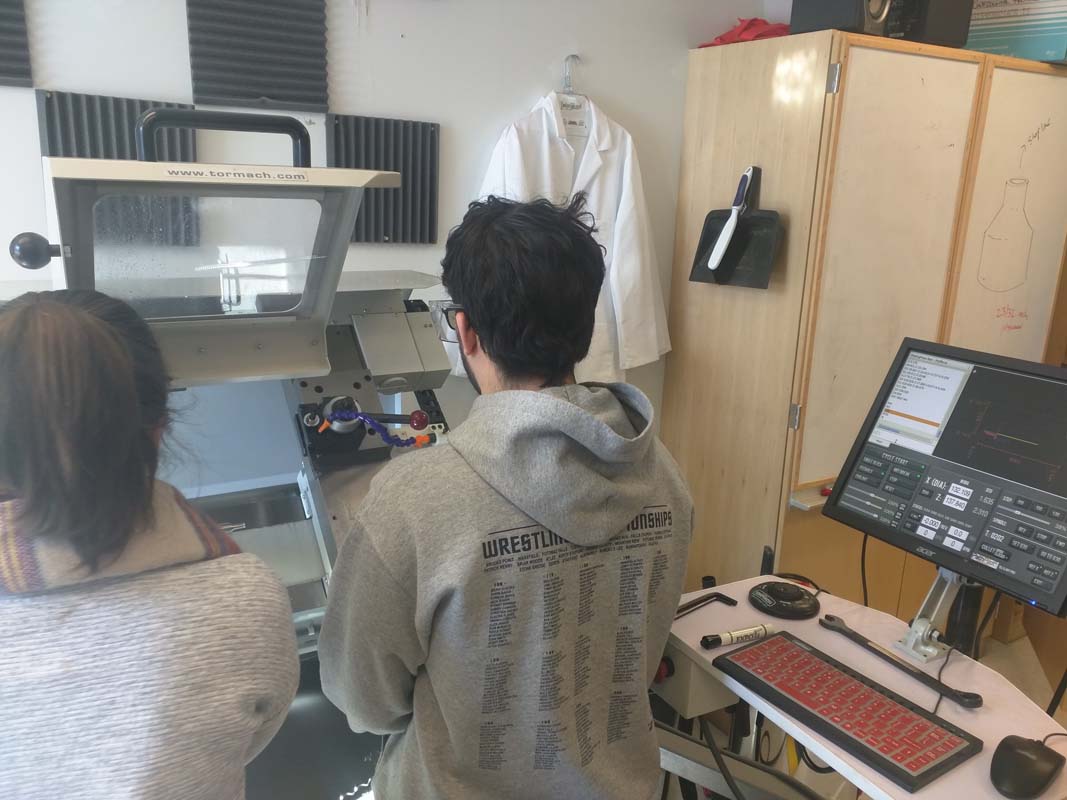

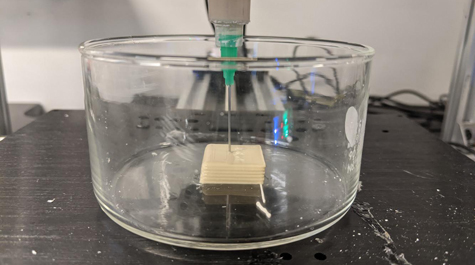

This is the basic head for the open source, 3D printable, syringe bot that we’ve completed, tested, and deployed. Here you can see it in action as used by Doctoral Candidate Stapel as it is being used to 3D print diatom-filled biogel structures:

Stapel & Advisor Dr. Hannes Schniepp continue to move forward with their cutting edge research into the 3D printing of biological structures, having now built this new expanded bioreactor to generate custom materials.

We will keep pushing forward with working on and improving ultra-low cost, high resolution, syringe bot design.

This version (0.1v) was designed and produced from scratch by Aidan Connor (Computer Science, ’21) and the Director of the Makerspaces. If you would like to become part of the open source design effort please contact the director at jfrey@wm.edu.

EPAD Capstones Head to the Finish Line

In case you’re not familiar, EPAD stands for Engineering, Physics & Applied Design and is a relatively new track developed as a venture between Physics & Applied Science. At the conclusion of a Physics-EPAD degree program the students have to undertake a year long engineering capstone project as a team that comes in a variety of flavors. As we head into the end of the AY20-21 year you can see some students working hard on their capstones.

Let’s make a Uke!

Have you ever made a ukelele using a CNC router? Want to learn? Take a look as one of our own goes through the process and makes his own! Here’s a video of the top being carved out on the router:

Pumps Galore

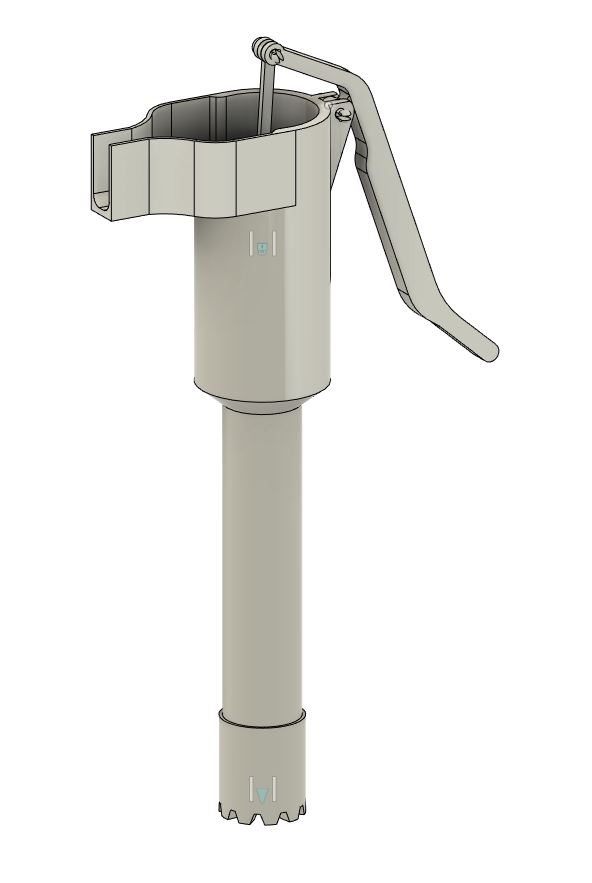

There comes a time during every semester of APSC251, Introduction to Engineering Design, wherein the students are expected to design, print and assemble working, fully 3D printed, water pumps. Some recent examples provided for them include a piston-style water pump and a centrifugal-style water pump as seen below. Checkout their operation and more videos on our YouTube channel here.

Drive to Subscribe

We thank you for doing your part to support the Makerspaces by subscribing to our YouTube Channel.

Did you know there are certain caps associated with YouTube accounts’ subscribers? As we drive to build a better website and offer more content including live streams, recorded how-tos, and more; we have discovered that we need to get over the first couple hurdles of having a set number of subscribers.

For example, right now we can embed recorded videos here for you to watch (like this clip of CNC milling the W&M logo for use in an injection mold):

However, we cannot embed live streams and other content from our YouTube channel until we get more subscribers. Moreover, until we get more subscribers we cannot rename the channel to something (anything) better than:

https://www.youtube.com/channel/UCxZLJZ46cAGjlIhdqnEUqQA

So, long and short, we thank you for doing your part to help us out by subscribing to our YouTube channel.

Renewing an Antique

This old printing press in the basement of Swem Library needed some love in order to be operational once again. After some disassembly, Jacob designed some replacement parts and manufactured them using the CNC lathe.