Semester End

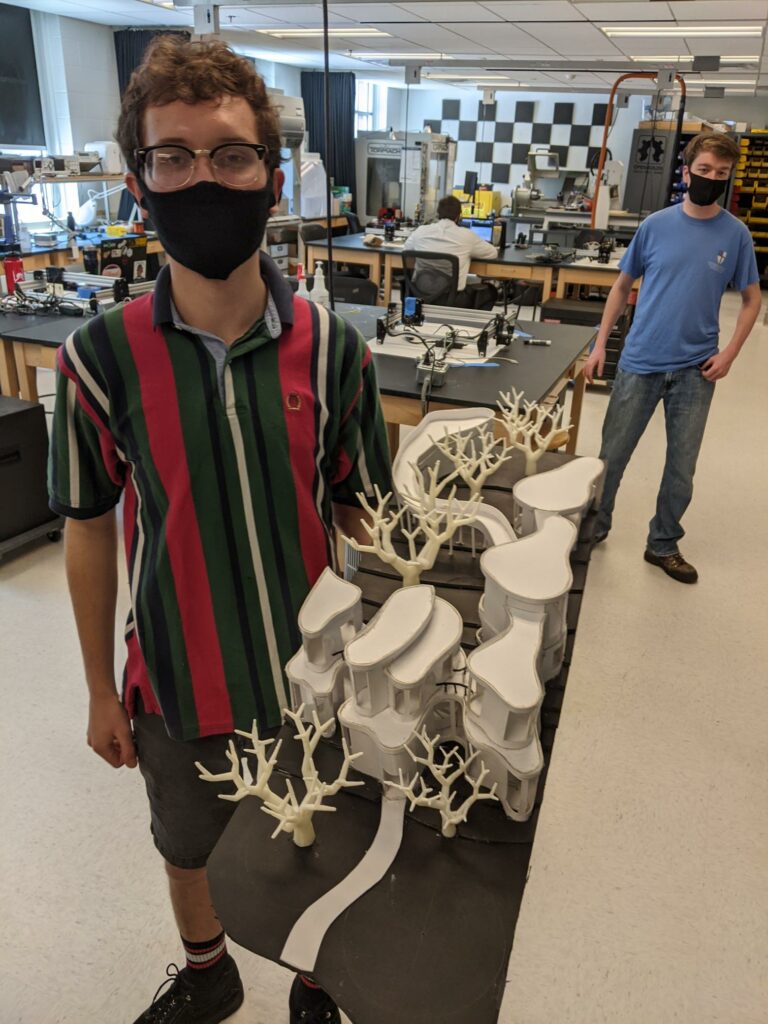

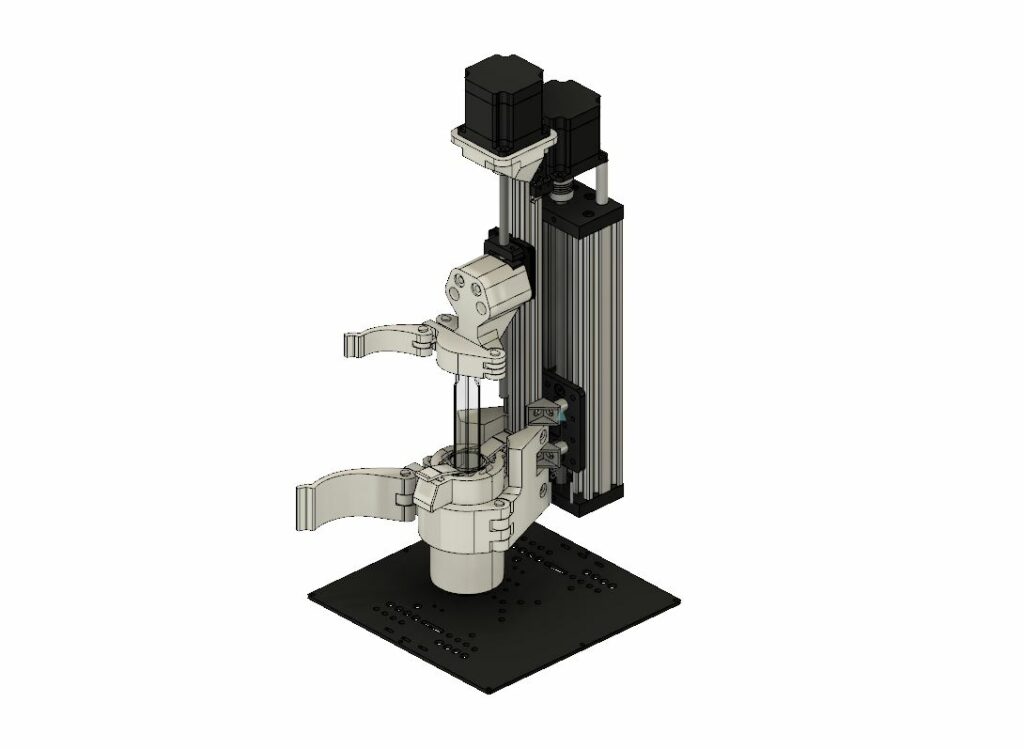

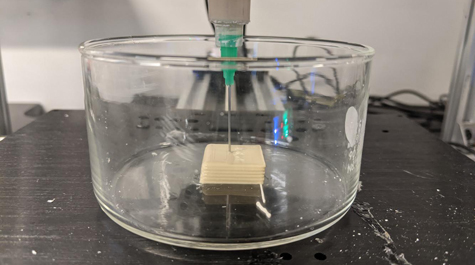

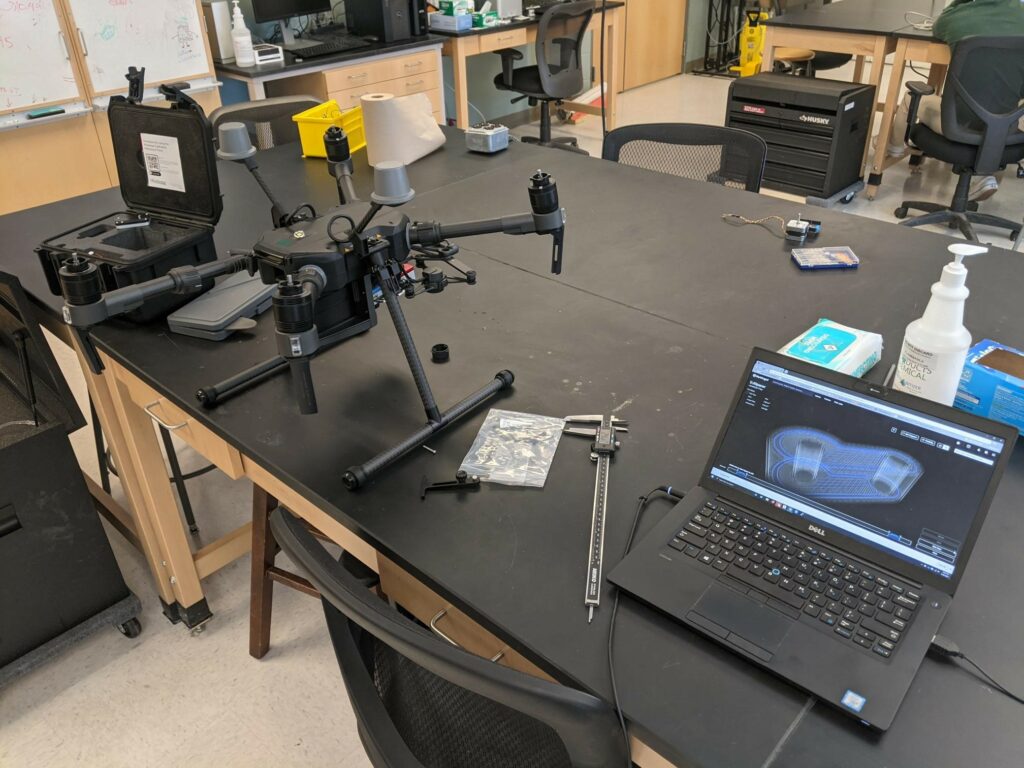

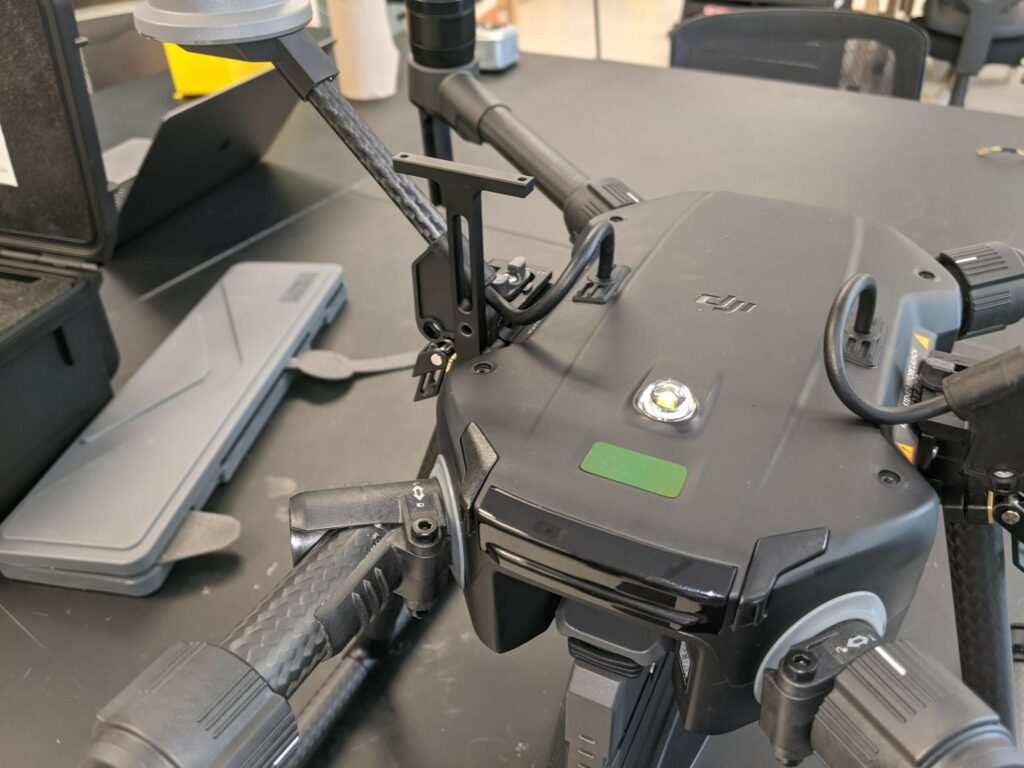

It has been quite the semester here in The Makerspaces. If you’ve been around, you’ve seen countless things get created, from the recent architectural adventures to working on concepts in autonomous boats, classwork involving 3D printed water pumps, custom solutions for research tools like the X-Ray Photoelectron Spectroscopy system at the Applied Research Center, working on setting up a 3D scanning lab, and hosting a sUAS pilot to discuss her roles at NASA.

There’s never a dull moment around here. As we head into the winter break you’ll still see some Makerspaces activity on campus, however, it is likely to be focused on maintenance & repair as well as gearing up for the spring semester.

After December 9th, feel free to stop by to make something by appointment only and with limited staff, additionally, stay tuned for the spring semester opening of our 3D scanning lab located adjacent-behind The Makerspaces at Swem Library wherein we’ll have multiple 3D scanning options for both small and large scales.

Good luck on Finals and we hope you have a wonderful holiday season and winter break! See you in the spring!