Summer 2022

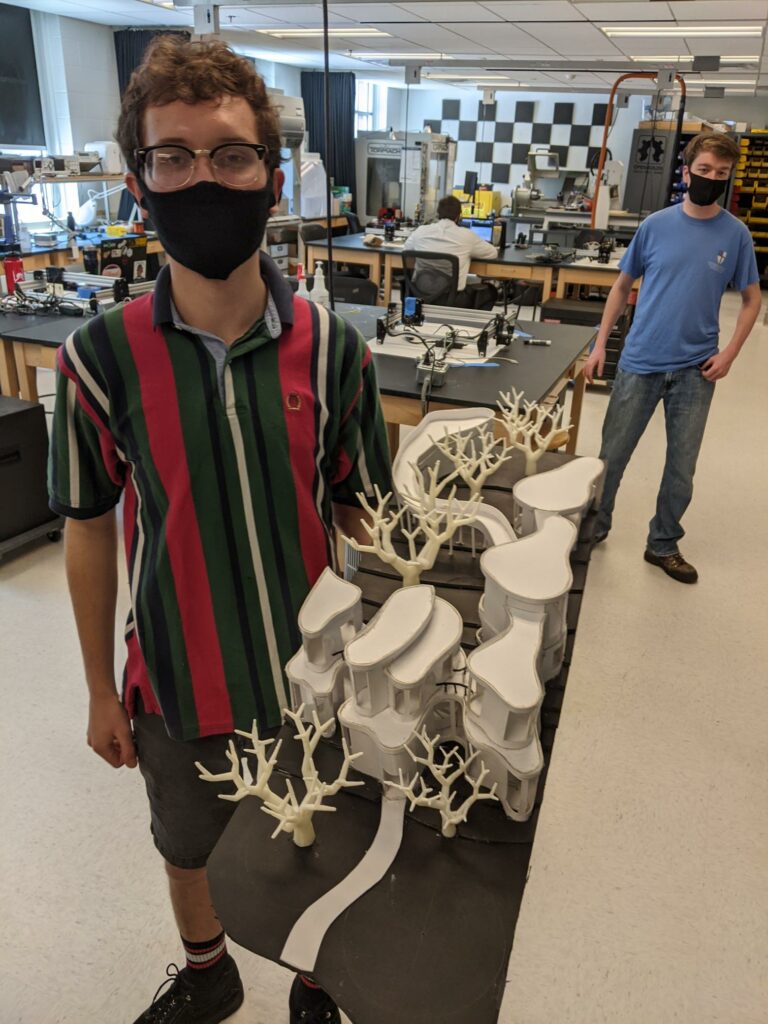

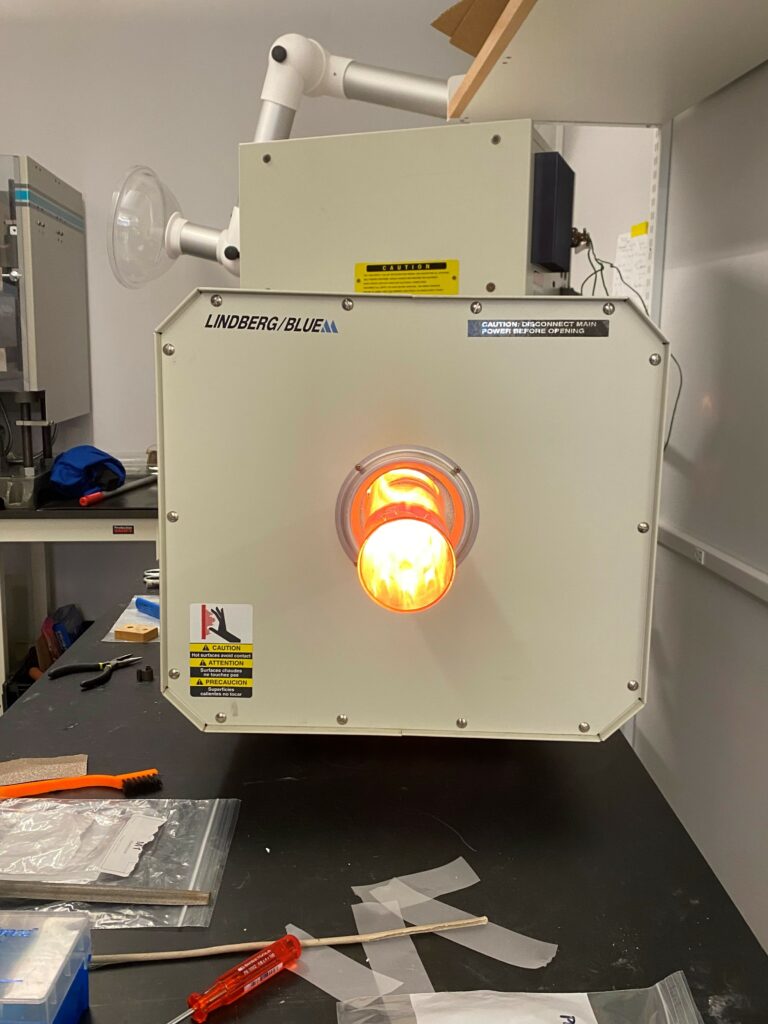

We are here. We are making things daily.

If you’re around campus this Summer guess what? So are we! We’ve started gearing up and getting ready to help with the School of Educations’ Camp Launch July 17th-30th as well as already starting to get ready for the Fall Semester! To get ready we’re cleaning, organizing, and training! If you are around and want to learn laser cutting, embroidery, CNC machining, or anything else with which we can help then schedule a session with us in the ‘Make an Appointment’ menu link. All summer long we’ll be here but by appointment only.